To supplement its cutting and marking technologies, MicroStep delivers a comprehensive line of drilling, tapping, countersinking and milling solutions that can be integrated within the same CNC machine, and many cases even on a single gantry.

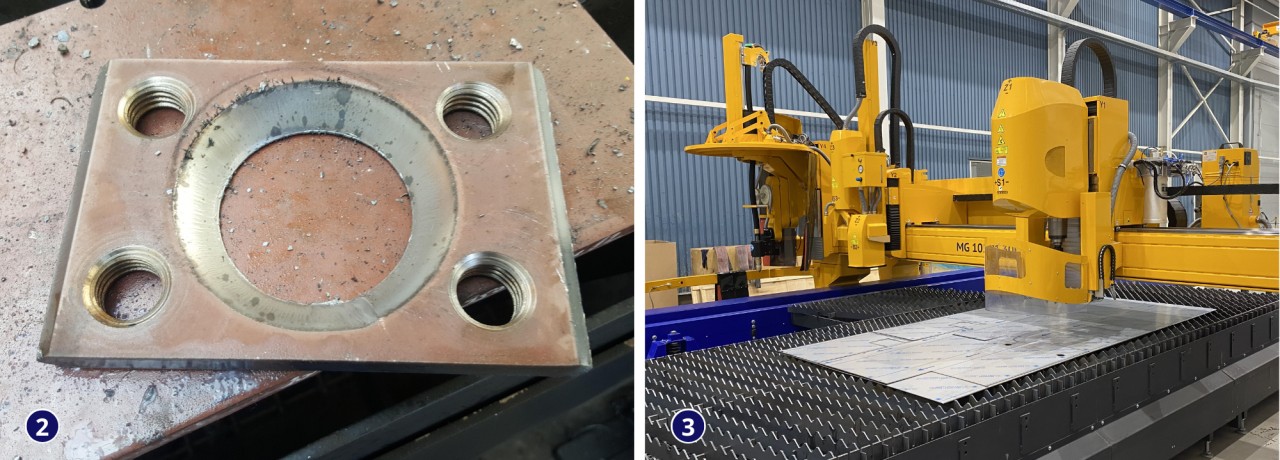

Fabrication processes often need high-precision holes, threads, or countersinks on parts. Whether it is flanges, end plates, heat exchanger tube sheets and generally any stress-exposed bolted joints, there is a fair number of applications where it is technologically necessary to make the holes by drilling. And while there are jobs – especially those with large quantities of holes in a single workpiece or assembly – where using a dedicated boring machine is most efficient, there are also many parts with just a couple of holes in them and perhaps some threads ❷ that are usually done manually, or in a separate mechanized drilling process, just for the lack of a better option. For these occasions, the ability to create parts on a single machine including cut contours, markings and machined holes makes the most sense economically.

❷ -

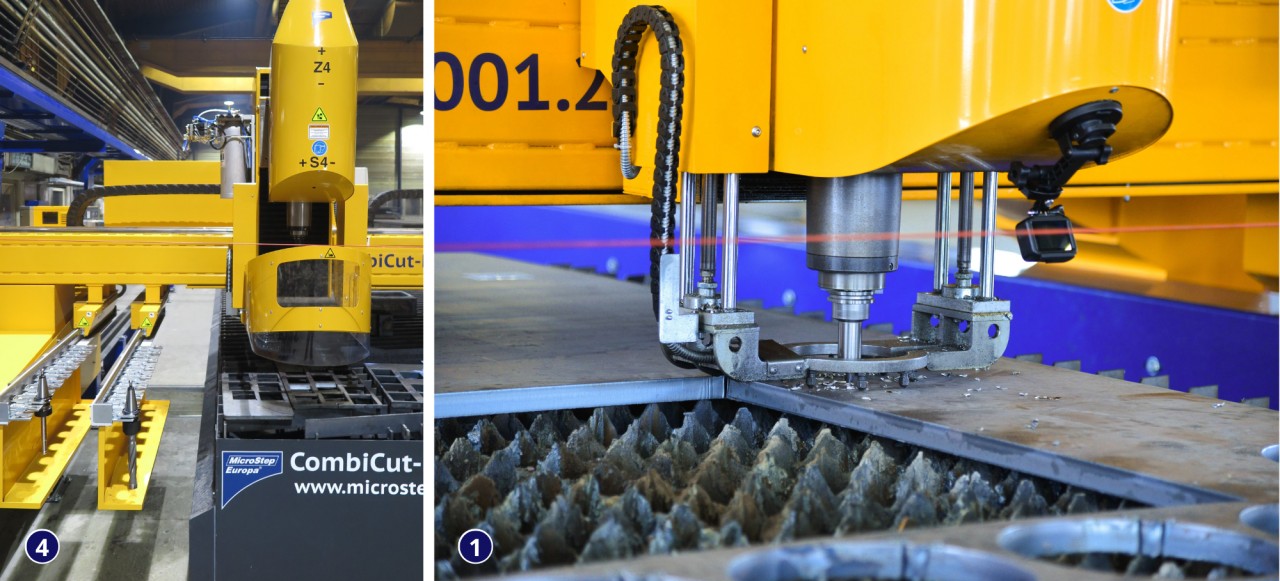

Hardox part drilled, tapped and bevel cut with plasma on MicroStep DRM machine.❸

- A multifunctional MicroStep machine with drilling up to Ø 40 mm (+ tapping and countersinking), inkjet marking and a special plasma bevel head up to 120° tilt angle and endless rotation for plate, pipe beam and dome cutting.

Automating technological operationsMoreover, integrating several technologies into a single multi-functional gantry ❸ allows the technological processes on a semi-product – be it plate, profile, beam or a pre-welded assembly – to be automated within one NC program. It is not only the automatic tool exchange, but also automatic switching between the different technologies, setting the sequence of operations for each part in advance while taking into account thermal expansion of material, and overall, the ability to set the most efficient process for producing of parts with the desired accuracy while having access to a combination of technologies. Input here is the raw semi-product – e.g. a metal plate loaded on the cutting table – and output are already finished parts that can have contours cut with straight edges up to complex bevels (without dross), drilled and countersunk holes, cut threads ❷ and laser marked data matrix codes for identification. The parts can then go straight to welding, blasting or whatever the production process requires next.

The customer achieves a significant increase in efficiency through reduction of technological steps (e.g. no need for deburring or manual grinding of cut holes), eliminates transfer of parts to different workstations (e.g. to a separate drilling station or a manual beveling workplace) and saves labour and time through automation. Additionally, initial investment in one multifunctional machine is less than in two or more machines, and also less floor space is required.

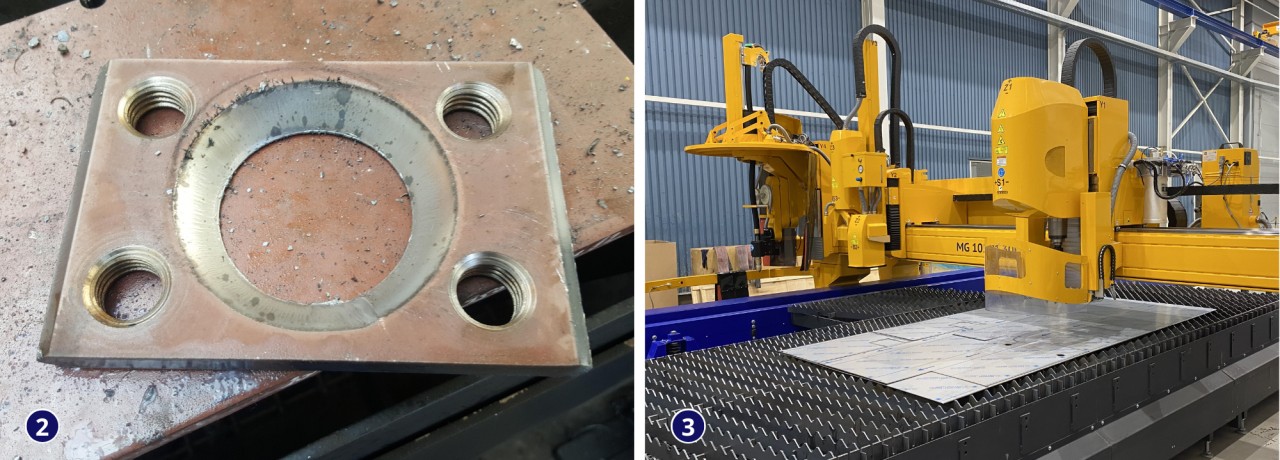

Drilling, tapping, countersinking – well tuned and field testedDuring the past two decades, MicroStep supplied hundreds of multifunctional machines with drilling capabilities, combining mostly plasma bevel and oxyfuel cutting with machining operations. The solutions include small drills up to Ø 13 mm as well as more rigid units with spindle powers 11 kW – 55 kW that cover drill diameters up to Ø 30 mm, Ø 40 mm and Ø 60 mm for drilling up to 100 mm thick plates. Pre-drilling units Ø 12 mm for thick oxyfuel piercing up to a 300 mm plate thickness are also available. The most popular choice is a 26 kW drill with diameter range Ø 4 mm – Ø 40 mm, countersinking and tapping up to M33 ❹.

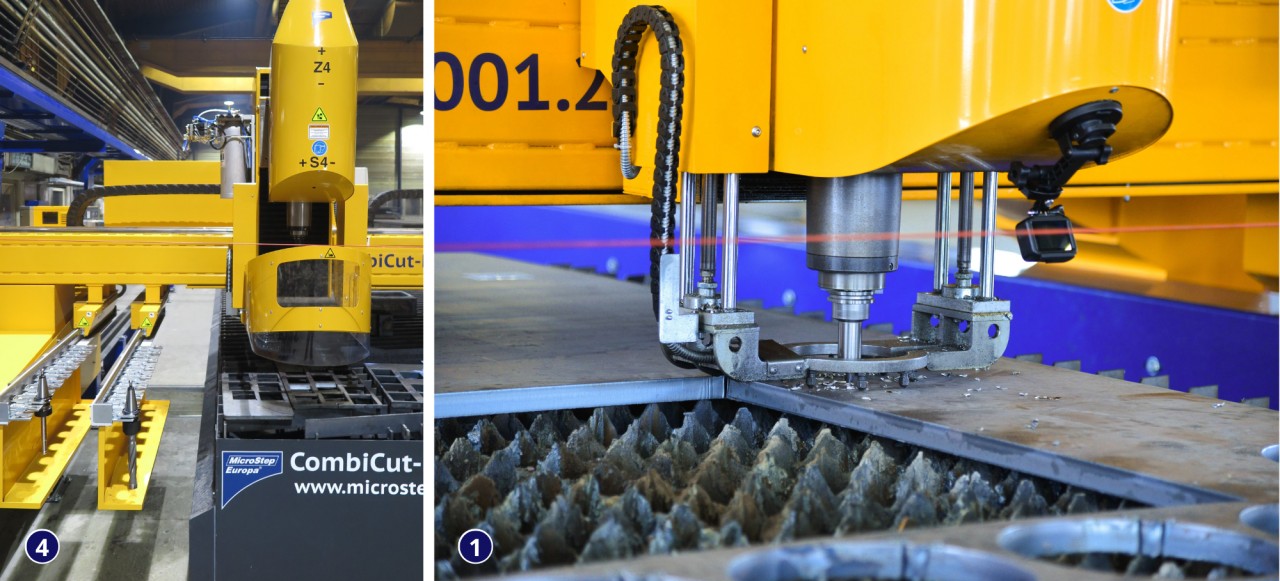

The drills come with automatic tool exchange and internal and external cooling of drill bits as well as with damage protection in case of tool breakage. High precision of countersinking is ensured by two incremental sensors in the pressure retainer that measure the distance between the plate and the countersinking tool ❶. The equipment includes automatic drill length calibration (ACDB technology) and supports various drilling cycle types including peck drilling.

❹

- MicroStep drilling head with internal cooling and automatic tool change, with automatic tool magazines for 16 tools.❶

- Precise countersinking on a MicroStep machine achieved thanks to plate distance sensors integrated in the pressure retainer on the drilling tool station.For heavy-duty drilling operations in the field of automated production of flanges, gussets and end plates, plate processors such as the MicroStep's DS series ❺ are the common solution. These machines are capable of fully automatic operation, with automated loading and unloading of material as well as work area cleaning by a brush and automatic removal of drill chips. For automated drilling and tapping of profiles with square or rectangular cross-section, the profile processing line DS-B ❻ with two drilling heads rotating on a slewing ring is the ideal solution. The machine provides simultaneous drilling and marking of two opposite sides of a profile while the material is loaded and unloaded automatically.

❺

- Plate processing line MicroStep DS with a 55 kW drill dedicated to automated production of flanges.❻

- Profile drilling line DS-B allows simultaneous drilling, tapping and marking of rectangular hollows sections up to 12 m long and 300 mm wide.For milling and routing operations on steel parts, MicroStep delivers its flagship multifunctional CNC machine with an independent sub-gantry and a powerful retainer that allows milling and drilling up to Ø 70 mm – the DRM Ma series.

Milling and heavy-duty drilling up to Ø 70 mmDRM Max is MicroStep's flagship in machining operations – a heavy-duty CNC cutting, drilling and milling machine ❽ with key applications in offshore, wind tower, heavy vessels, columns, reactors and heavy-duty machinery segments. Its gantry has a rigid double-beam structure with an independent sub-gantry carrying a 55 kW spindle and two powerful retainers that clamp down with 24,000 N each, over a 750 mm wide drilling and milling area ❾. This robust machine design enables drilling up to Ø 70 mm and a variety of milling operations such as large hole milling, face milling, pocket & slot milling, chamfer milling, thread milling or counter boring ❿. DRM Max can be also equipped with other accessories of the DRM series enabling plate, pipe, beam and dome cutting applications.

Features & Benefits (DRM Max milling + drilling)

- 750 mm wide drilling and milling area

- 2 powerful pneumatic retainers

- Minimal chip-to-chip time

- Fast processing & tool exchange

- Automatic internal and external tool cooling, tool exchange magazine, cleaning of processing area, drill length calibration (ACDB technology)

Plasma and oxyfuel machines

Plasma and oxyfuel machinesIntegrating drilling solutions into plasma and oxyfuel cutting machines makes a lot of sense since metal parts produced from mid-range to higher thicknesses often contain holes, threads or countersinks. For very thick materials ( ̴300 mm), drilled holes can be used as material piercings for subsequent oxyfuel cutting. MicroStep drilling solutions cover a broad range of diameters between Ø 4 – Ø 60 mm (and even Ø 70 mm in case of DRM Max) and taps between M4 – M33. Tool magazines for up to 8 tools ⓫ with a possibility to have them coupled up to 16 positions allow for automatic switching of tools within a single cutting plan.

Lasers with drillingIt’s not only plasma and oxyfuel machines that bring the advantage of multi-functional design, but also MicroStep's waterjet and fiber laser machines. For the latter, a turret head with 6 tools and automatic drill bit calibration ❼ provides drilling up to Ø 20 mm, tapping up to M16 and countersinking capabilities while a stronger drill up to Ø 30 mm is available for MSF Max laser machines with steady cutting tables (without pallet changers).

❼

- Calibrating a turret drill head on a MicroStep fiber laser machine with drilling/tapping/countersinking option Waterjet with tappingWaterjet machines do not usually come with drilling feature because the technology is precise enough to cut holes with sufficient quality. MicroStep supplies slam-diameter pre-drilling units though. They are used for piercing of sandwich material whose inner structure would otherwise erode if pierced directly by the water beam. Bigger spindles are used for tapping of holes after they are cut by water. MicroStep supplies tapping tool stations up to M16 for its Aquacut series.