Whether it is manufacturers of cranes, excavators or other construction machinery: large and small companies rely on the groundwork of ZKS Łabędy Sp. z o.o. from southern Poland. The 2003 founded company delivers custom-made welded structures and assemblies for a wide variety of requirements. MicroStep cutting machines have proven themselves as reliable production tools, delivering consistent quality output. "I can only recommend MicroStep to all companies planning to buy a plasma cutting system," says Łukasz Jastrzębski, foreman at ZKS.

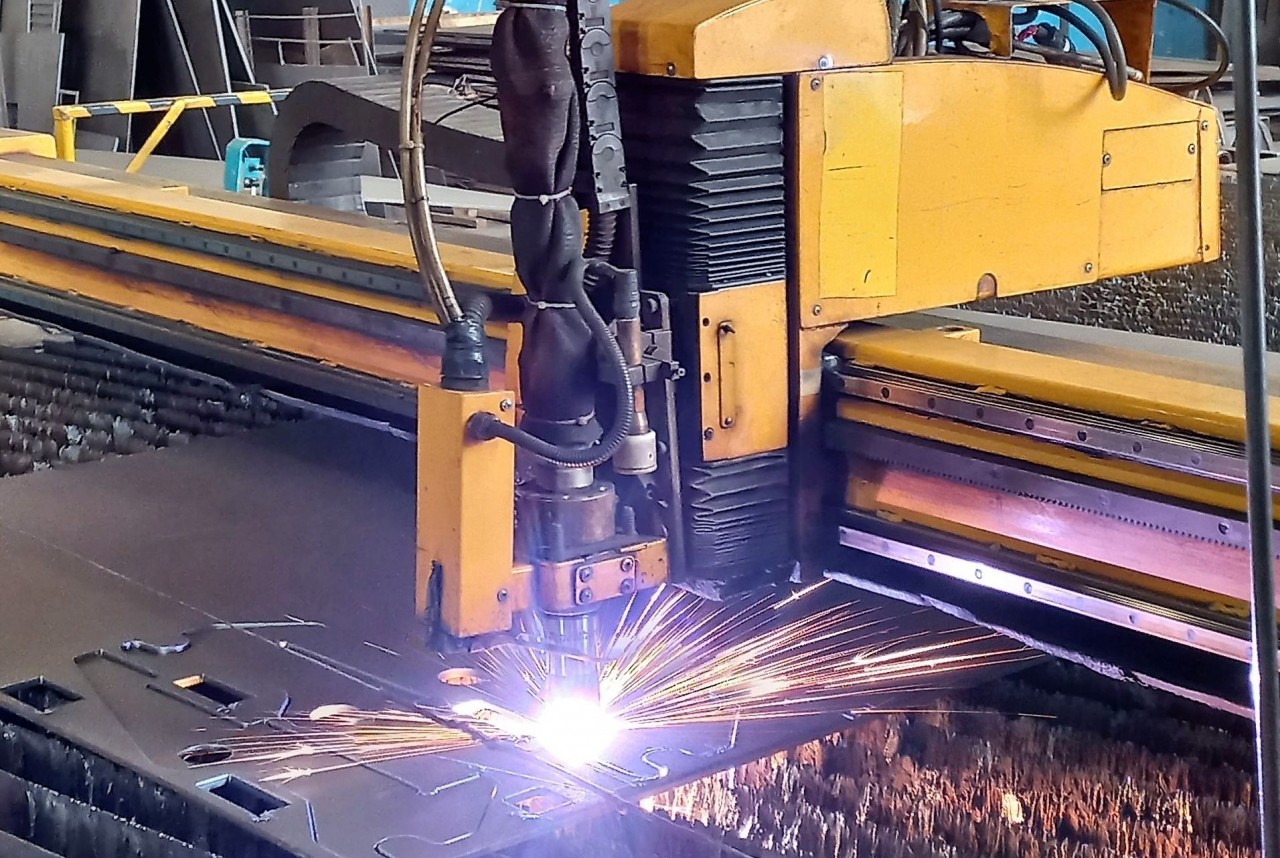

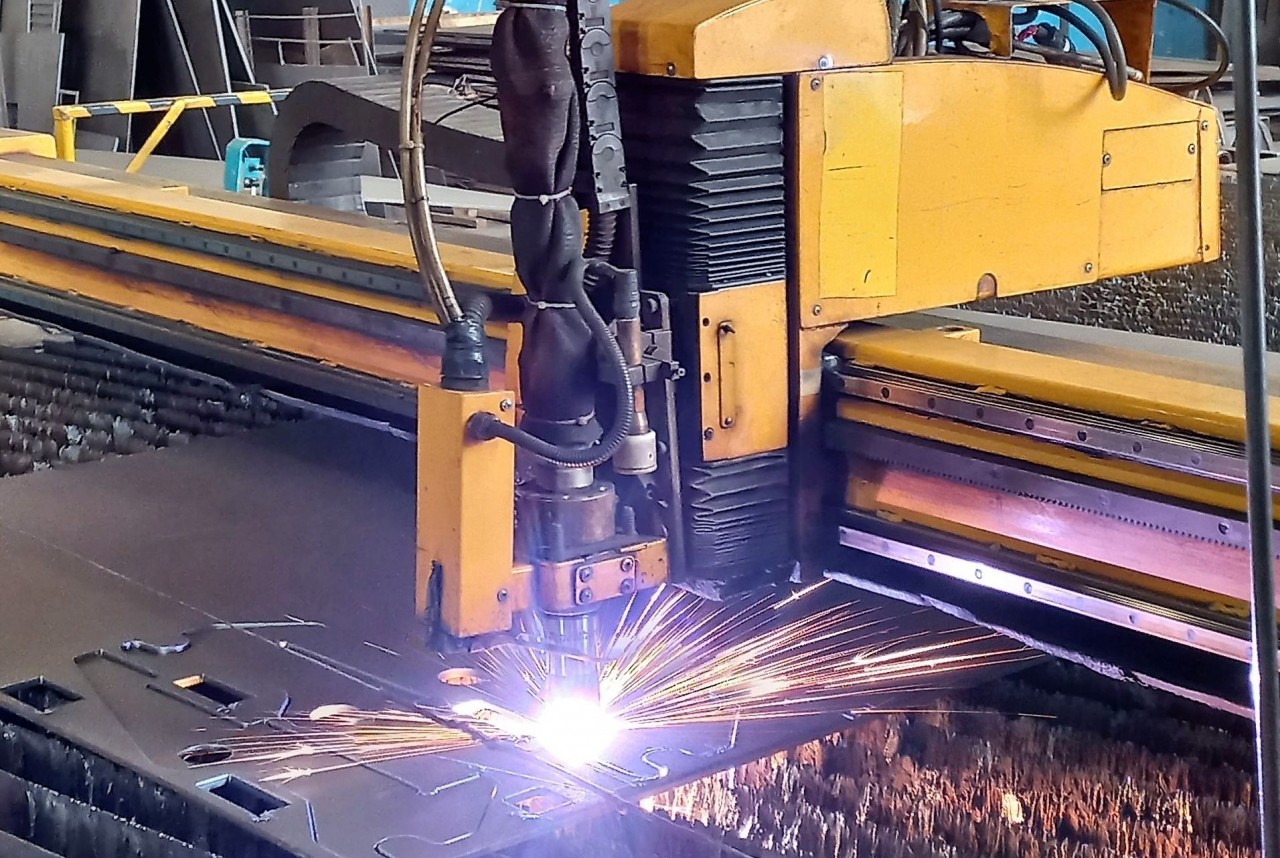

The MG at ZKS with plasma rotator and inkjet marking unit.The Upper Silesian city Gliwice located in southern Poland between Wroclaw and Kraków is home to ZKS Łabędy Sp. z o.o., a contractor producing mainly heavy welded structures. The company processes high-strength, fine-grained difficult-to-weld structural steels to produce load-bearing structures for global players in the construction machinery sector, e.g. for cranes and excavators. "The focus of cutting in our production is on steel elements for these industries," says Łukasz Jastrzębski, who has been with ZKS since 2004 and is the foreman responsible for the machine park.

MicroStep's plasma rotator provides automated weld seam preparation up to 50°. The search for a satisfactory solution for cutting the up to 40 mm thick sheets was a long one. Different cutting technologies from different manufacturers were previously in use. "We wanted to invest in machinery because we weren't really satisfied with the output of existing machines," says Jastrzębski. Finally, in 2007, they invested in a 2D plasma cutting system from MicroStep and later in the same year in a bevel cutting system with two 3D plasma cutting heads. In 2019 it was time to modernize and strengthen the machine park. After 12 satisfying years it was clear: it will be MicroStep again. The new machine was selected according to the following criteria: cutting times, reliability, piercing and cutting capacities and an intuitive software environment. All requirements matched with MicroStep's all-rounder series MG. "The cut parts are of very high quality," says Jastrzębski.

The first plasma cutting machine at ZKS was installed in 2007. The 2D cutting system Is still in operation today.Automated weld seam preparations are a big plus in productionCommissioning took place at the beginning of 2020. Since then, the steel service center has been constantly using their 3D plasma cutting machine in a two-shift operation, and occasionally also in three shifts. Having a plasma rotator and inkjet marker, 3D processing of large-format sheets is possible without any problems. Automated weld seam preparations are also a great advantage due to the many subsequent welding tasks. For the machine park manager, the conclusion is easy to draw - the decision was worth it: "I can only recommend MicroStep to all companies planning to buy a plasma cutting system. It's the best on the market.”

In early 2008 a further MicroStep cutting machine of the MG series was installed. It includes two plasma rotators for parallel bevel cutting.MG series 3D plasma cutting machine with a work area of 12,000 x 2,500 mmAfter investing in a 2D plasma cutting system and a 3D plasma cutting solution with two bevel units in 2007, the Polish company opted for MicroStep again in 2020. ZKS relies on MicroStep's all-rounder series MG. The cutting machine is configured for 3D processing of sheet metal with a work area of 12,000 x 2,500 mm. Included is MicroStep's plasma rotator for bevel cutting (for example weld seam preparation) with a tilt up to 50°. The machine can cut sheets up to 40 mm thick thanks to Hypertherm's state-of-the-art XPR 300 plasma source while consistent accuracy of bevel cuts is ensured by MicroStep's patented ACTG® calibration unit. Additionally, the machine has also an inkjet marking unit. This allows to quickly add desired markings to the corresponding components or rest plates.