When it comes to air-conditioning, Gree Electric Appliances Inc. are the world's number one. In their production facilities, the company relies on pipe cutting solutions from MicroStep.The HQ of Gree is located in the vibrant city of Zhuhai right next to Macao; here the company develops and manufactures air conditioning units with a turnover of more than 13 billion euros per year. Since 2012, Gree has been led by the businesswoman Dong Mingzhu whose mission was to transform the company from an air-conditioner producer into a versatile manufacturer with focus on smart home appliances. New York Times titled her “one of the toughest businesswoman in China” and her autobiography has even been adapted into a TV series in China. Since inception, the company experienced tremendous growth and with over 70,000 employees and more than 60 million air conditioning units manufactured annually it ranks among biggest companies in its field.

Gree Electric Appliances Inc. participated on prestigious projects such as the National Stadium (Soccer City) in South Africa’s Johannesburg.

Gree Electric Appliances Inc. participated on prestigious projects such as the National Stadium (Soccer City) in South Africa’s Johannesburg.Air conditioning solutions from Gree find their application in many housing and industrial facilities worldwide, from single family homes up to large prestigious projects such as the site of the final match of the 2010 Football World Cup, the National Stadium in South Africa (Soccer City) in Johannesburg. Projects like these require a high degree of precision when manufacturing components. Big construction projects in particular require very long pipes to be cut with utmost accuracy.

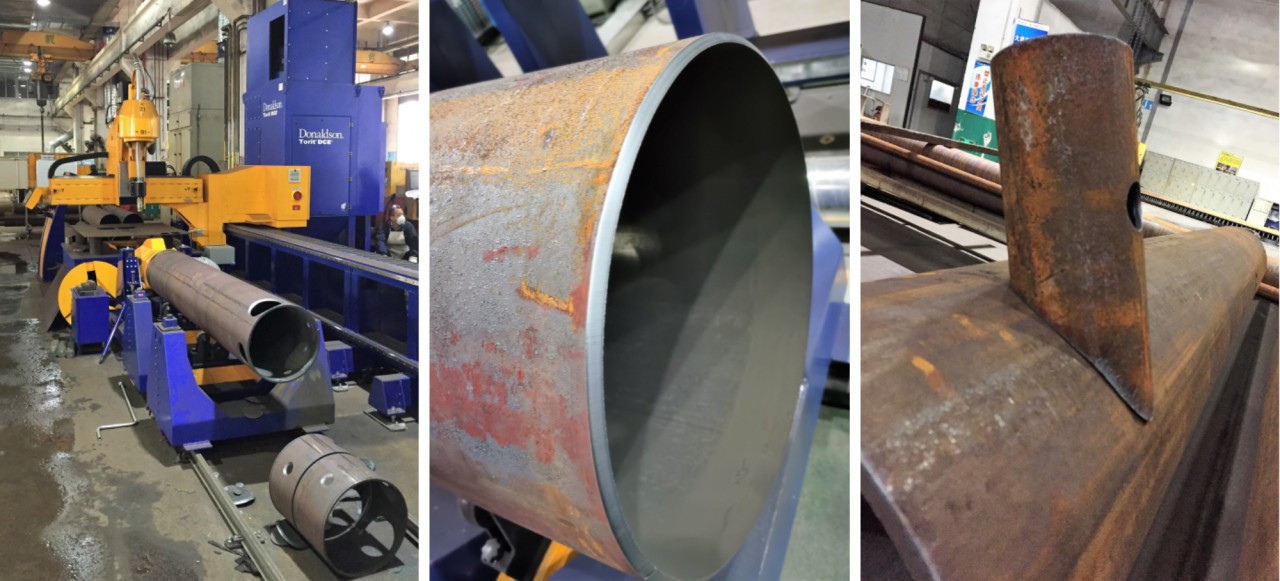

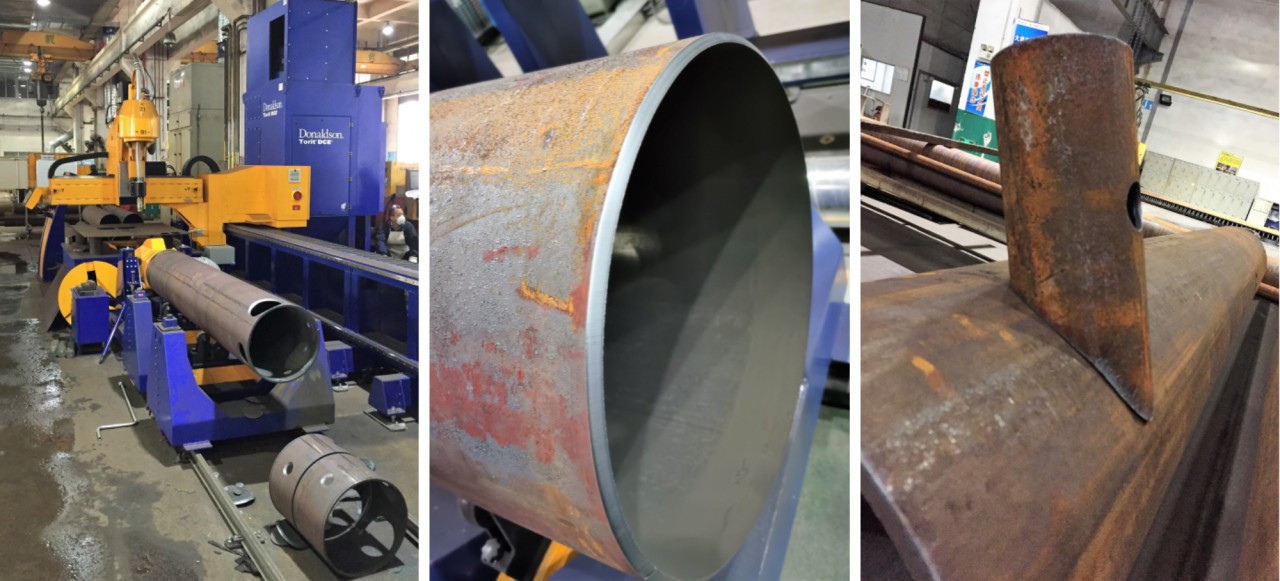

Gree’s three combined pipe & dome cutting machines from the PipeCut series allow to cut pipes up to Ø 610 mm and a length of 12 m as well as domes up to Ø 1,200 mm.

Gree’s three combined pipe & dome cutting machines from the PipeCut series allow to cut pipes up to Ø 610 mm and a length of 12 m as well as domes up to Ø 1,200 mm.

In 2016, Gree went on to look for a new cutting solution that would suit their needs – a combined system for weld preparation on pipes and smaller domes. The decision fell on a MicroStep PipeCut machine for processing of pipes with a length up to 12 meters and a maximum diameter of 610 mm. The machine is equipped with MicroStep’s industry-proven plasma bevel tool station with auto-calibration that enables easy and precise bevel cutting and trimming of pipes up to 45° with edge preparation for welding. Further in accordance with the production requirements, the machine design has been tailored to include a 1,400 x 1,400 mm cutting table for 3D processing of dished ends – all programmable with MicroStep’s 3D CAM software mCAM.

Thanks to good experience with the first solution, Gree purchased further two similiar PipeCut machines in the course of 2019 and 2020 for their Changsha and Hefei production bases.