The company has been processing stainless steel with technologies ranging from sawing and CNC turning to bending, laser cutting – both sheet and tube – and deburring, finishing and more. “Despite all our options, we felt there was room for even more,” Mr. Meijering continues. Following the advice of an acquaintance, he contacted the specialist MicroStep dealer in Benelux, Wouters Cutting & Welding. In December 2019, together they added another technology to the company’s toolbox: plasma cutting.

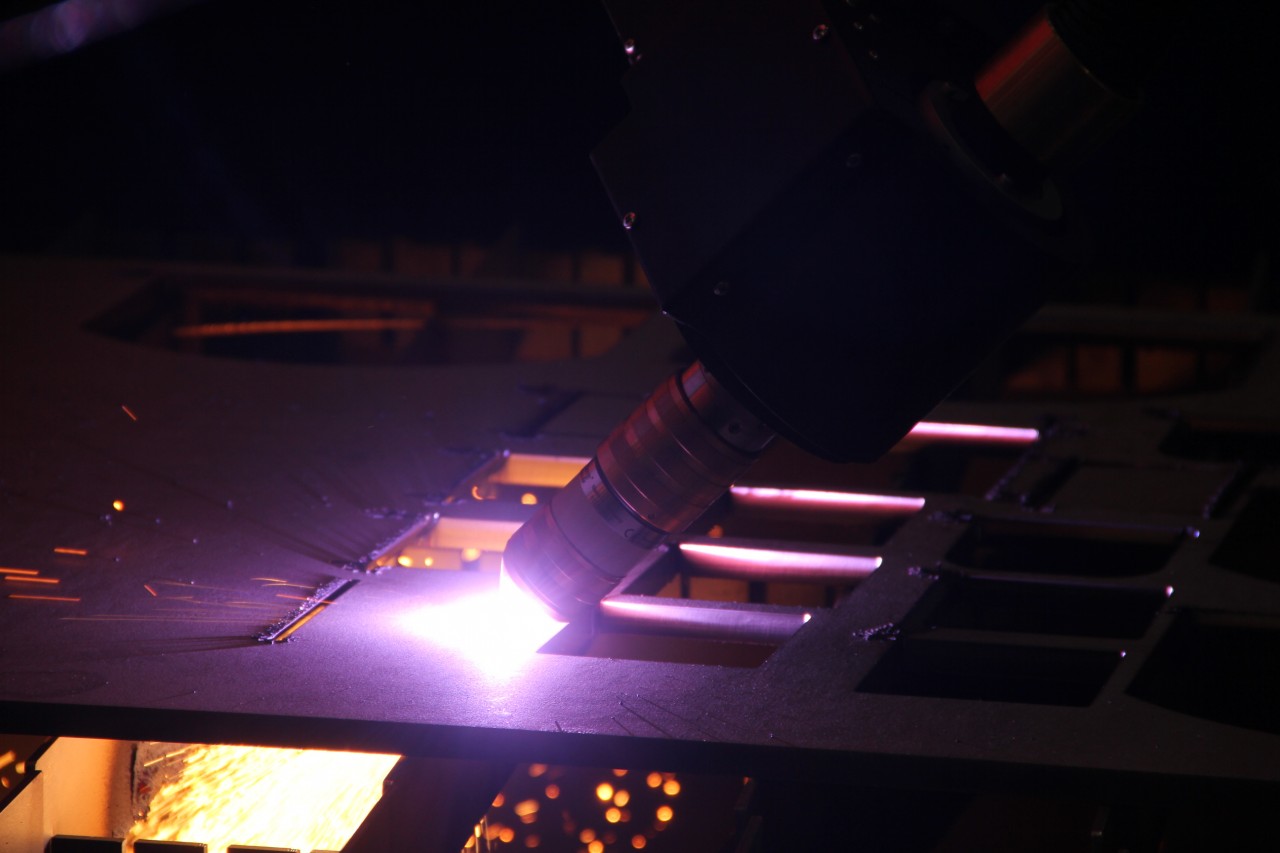

The MicroStep MG plasma cutting machine designed for 3D sheet metal and pipe processing.

After an analysis of their needs and a several consultation appointments, the stainless steel wholesaler decided on an MG-series plasma cutting system, the all-rounder from MicroStep. With the configuration MG 12001.25PRK+CH1200P, the CNC machine was designed for 3D sheet metal and pipe processing, working with geometries that the company processes on a daily basis. With the new investment, it is possible to process sheets with dimensions of 12 000 x 2 500 mm and pipes with a diameter of 750 mm and a weight of 7 t. “We want to be prepared for the requirements of our customers in the future. This gives us the flexibility we need,” says Mr. Meijering. “One of the options on the MicroStep machine is bevel cutting, i.e. cutting at an angle. In this case, this can be done at an angle of up to 50°,” explains Nic Wouters of Wouters Cutting & Welding. “This extra option was not immediately out of necessity, but out of opportunity. We always try to think more broadly and anticipate what is yet to come,” Mr. Meijering adds.

Paul Meijering (left) and Nic Wouters (right) at the new machine.

Mr. Wouters mediated the plasma cutting system and took care of the production analysis and advice: "The biggest advantage of the cutting system is its flexibility." Cutting sheet metal and tubes, separating cuts, 2D contours or bevel cuts up to 50° for weld preparation - everything is possible for different workpiece sizes. For the plasma power source, the company relies on a Kjellberg HiFocus 440i neo. "This means that stainless steel can be cut up to a thickness of 120 mm," explains Nic Wouters.

Paul Meijering is satisfied with his new investment: “We are able to produce more cheaply and easily and faster with the MicroStep. That way we will now be able to help our customers even better. We can only rate MicroStep positively."

The bevel cutting head with a plasma source from Kjellberg.