The paper describes a fully automatic CNC cutting line system consisting of several CNC cutting machines, an automated overhead crane for automatic sheet handling and further manipulation/handling equipment. The line operates in a fully automatic mode managed by MicroStep’s CAPP software solution MPM for automation of the production workflow. Copyright © 2002 IFAC

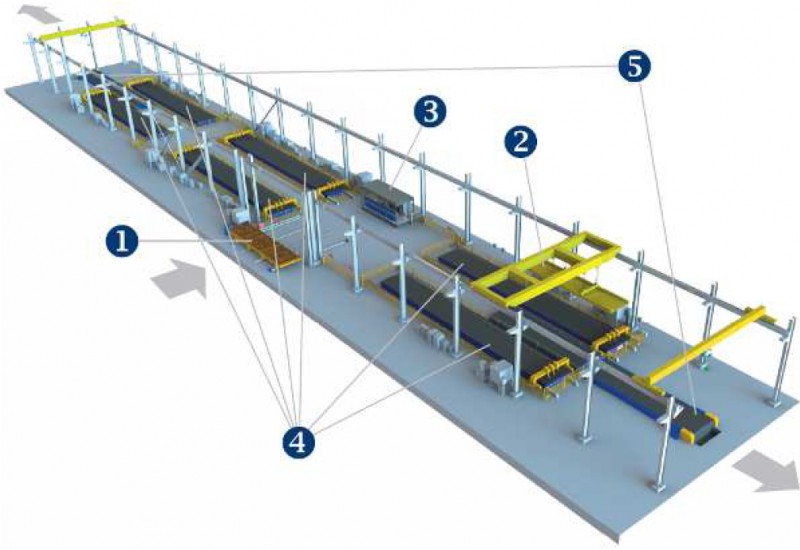

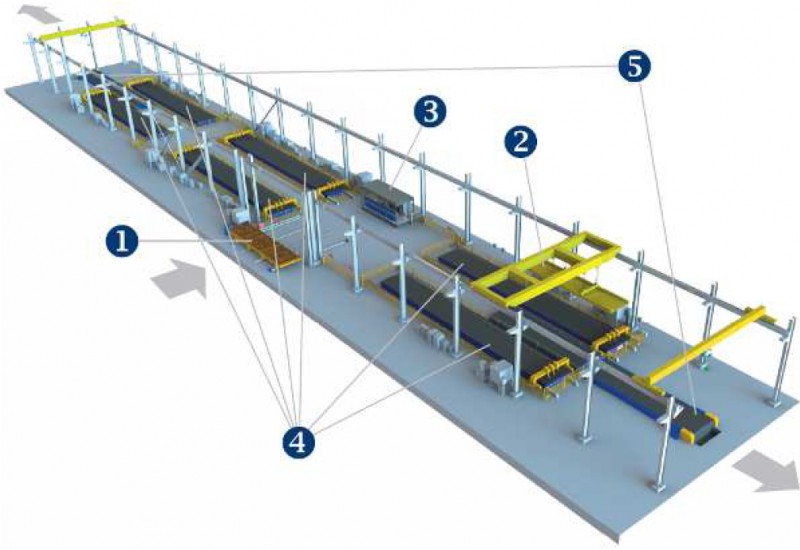

Fig. 1. Automated CNC cutting line MicroStep – Terex/Demag.

AUTOMATION REQUIREMENTS IN ENGINEERING

The current trend in engineering mass production (shipbuilding and offshore, production of steel structures in various industries, production of mining and agricultural vehicles, etc.) is active integration of machine tools to centrally controlled production processes – by automating the flow of material to and from machines through feeding, lifting and conveying systems and by software resources that provide communication between machines and applications of central production management.

In a number of cases, customers require delivery of complete production line solutions that would cover the entire production process from initial recording of orders and materials available to issuing final certificates of order execution or a finished product.

Large producers also require a high degree of automation involving not only the production process itself and the flow of material but also central stock management, database recording of parts and products and central order administration including the possibility to connect a machine or a production line to the corporate ERP system. Addressing these issues requires design flexibility from the machinery suppliers - the ability to deliver solutions tailored to the specific production requirements and spatial disposition of the production hall and, last but not least, interconnection of various control systems for individual machine tools to designer CAM software with an ability to provide and process feedback information on the results of cutting.

The aim is to increase work efficiency, to optimize manufacturing processes as well as to minimize costs and risks - the whole production should be fast, smooth, and transparent, with the possibility of being monitored by means of a corporate network.

AUTOMATED PRODUCTION

An example of such a solution is a unique project of an automatic CNC cutting line, produced last year by MicroStep in cooperation with the German division of Terex Material Handling (manufacturer of Demag cranes) in the Chinese city of Zhengzhou. The line (visualization in Fig. 2) consists of six CNC cutting tables MicroStep CombiCut with the cutting surface of 28 x 3 m, mounted with eight cutting portals (two of the cutting machines have two portals). Each of the portals is equipped with two plasma cutting heads (HD plasma sources Kjellberg HiFocus 360i) and an inkjet marker, enabling multi-line marking of the sheets with a speed of up to 20 m/min.

Fig. 2. Visualization of the workplace; 1) entry wagon, 2) automated crane; 3) control cabin; 4) CNC cutting machines; 5) output conveyors

Other parts of the line are an automated overhead Demag crane (9 t x 16.5 m), for handling semiproducts in the working zone (loading sheets on machines and transporting cut material to output conveyors), an input wagon for bringing the semiproducts from an external warehouse and two output conveyor tables, used for unloading the cut-out parts and transporting residual waste material into floor containers. The whole line operates in a fully automatic mode using a software package for production management, MicroStep MPM (Kováč, 2013), with integrated control software for the crane and material handling equipment by Terex/Demag. The database module screen of MPM is shown in Fig. 4.

Fig. 3. Control cabin with 8 consoles of MicroStep control systems |

Fig. 4. MicroStep Production Management (MPM) – Parts database. |

Fig. 5. Output conveyor with an underground container for small waste material |

Starting with automatic nesting (effective distribution of parts on a sheet in order to minimize waste after cutting) and cutting plans creation in the MicroStep Asper® CAM program, through automated loading of semi-products by the crane, distribution of cutting plans to individual machines based on parameters of the loaded material, automatic scanning of sheet position and start of cutting, to automatically calling the crane to unload material after cutting - the whole process is fully automated, i.e. without active operator intervention. The line operator has only a supervisory and service function - they monitor the line's function and make/respond to service reports of machines (e.g. replacement of consumables). Service personnel is also employed for material handling outside the line's working zone - loading sheets onto the input wagon and removing cut-out parts at the end of the output conveyor (Fig. 5).

Fig. 6. View of the workplace with the input wagon inserted in the working zone

SIGNIFICANT INCREASE IN EFFICIENCY

The end customer - the Zhengzhou Coal Mining Machinery company (ZMJ) is a leading Chinese manufacturer of excavating and mining systems with a major share of the Chinese market. The described automatic line is involved in production of one of the company's main products - hydraulic roof supports (Fig. 7). The line has replaced the conventional manufacturing process of cutting the parts with oxygen flame on separately standing machines. Thanks to use of modern HD plasma technology, and particularly to automating the production preparation, distribution of cutting plans and material handling, significant improvements were achieved - not only in the quality of the cut, but also in production efficiency - up to a 75 % increase in efficiency was achieved as one production cycle currently lasts 1-2 hours instead of the original 4-8 hours. In addition, the line increased the factory's production capacity by 40 % to 28,000 tons per month. The line has been designed to process 8,000 to 12,000 tons of structural steel per month in threeshift operation (Kováč, 2013).

Fig. 7. The final product - a hydraulic roof support |

Fig. 8. The cut parts |

GENERAL TREND

The general trend in metal engineering and steel processing workshops (not only those of major producers but also in middle-sized enterprises) aims at effective automation and smooth material flow hand in hand with the reduction of technological steps necessary for production of the desired final product or assembly. Besides integration into production lines via transporting and handling systems (apart from cranes it can be various shuttle tables, fork feeders, hydraulic lifting tables, cutting tables with built-in roller conveyors, chain conveyors or robot manipulators), the contemporary CNC cutting machines themselves are able to integrate several machining technologies on a single gantry – a combination of plasma, oxyfuel (and also waterjet) cut within a single cutting plan is a real option, along with marking with inkjet or micropercussion pins, drilling, threading, countersinking and last but not least – automated preparation of weld edges with bevel tool stations (Varga, 2013). As shown on the above mentioned example of cutting line, large setups with several big-sized machines and supporting equipment, automated for delivering heavy duty three-shift operation with minimum staff and yet high-precision output are no longer just visions for the future, but have already proven sustainability in daily operation.

REFERENCESKováč, M. (2013). MPM: Efektívny manažment výroby. Strojárstvo-Strojírenství, vol. 5, p. 88- 90.

Kováč, M. (2013). Automatizovaná rezacia linka. Zvárač, vol. 4, p. 39-41.

Varga, A. (2013). Plasmaschneidanlagen der neuen Generation. Blechtechnik, vol. 4, p. 24-27.