3D cutting solutions for steel constructions

Apart from standard flat-bed machines, MicroStep offers an exceptional variety of equipment for processing of 3D rotary objects and structural steel sections of various shapes. The rotary objects include differently sized circular, square and rectangular hollow sections (diameters of circular sections reach from Ø 30 mm up to Ø 3,000 mm), conical pipes, torispherical or elliptical domes and elbows.

Standard configuration of a MicroStep machine in sheet and pipe cutting execution consists of a cutting table for placing the sheets and an extracted channel for pipe positioning that is placed along the longitudinal side of table. The pipes are clamped in a rotary pipe cutting device located at one end of the channel. The cutting process involves a combination of movements: a gantry, a tool station – alternatively a bevel tool station – and the pipe cutting device are synchronized for a precise positioning of the pipe towards the cutting tool. In addition, special adapters for clamping of polygonal profiles or elbows can be attached to the pipe cutting device. For cutting of domes, a dome cutting area can be located behind or in front of the cutting table. A single cutting tool is used to process all different shapes of material.

|  |

In addition, for applications in the structural steel industry MicroStep developed a product line of specialized machines for cutting of structural steel sections as well as single-purpose machines for automated cutting and drilling of flanged parts. These machines can be supplied in various executions depending on types and sizes of the processed material or the requirements for automation of material input and/or part output, and eventually connected to a production line in the customer´s facility.

For cutting of hollow structures of circular and rectangular cross-sections we supply cutting machines PipeCut and CPCut. Both systems are of a modular execution that enables configuration of their deliveries according to particular requirements of customers’ production. PipeCut machines can have a working length of 3 m, 6 m or 12 m and process pipes with diameters ranging from Ø 50 mm to Ø 800 mm. The maximum wall thickness is 50 mm for plasma cutting (depending on the capacity of the plasma source), and up to 100 mm for oxyfuel. On the other hand, CPCut machines can also process large-sized pipes with diameters of up to Ø 3,000 mm.

|  |

Depending on the range of cut diameters and wall thicknesses, these machines are equipped with various supporting systems ensuring support of the cut profile during the cutting process. These can be easily adjusted for required profile dimensions in a certain limited extent or exchanged for a different range of dimensions. A cutting machine can be equipped with a beveling tool station with a torch tilt range of ± 50° that enables cutting with automatic weld preparation, even for complex intersection of pipes, or pipes and rectangular profiles.

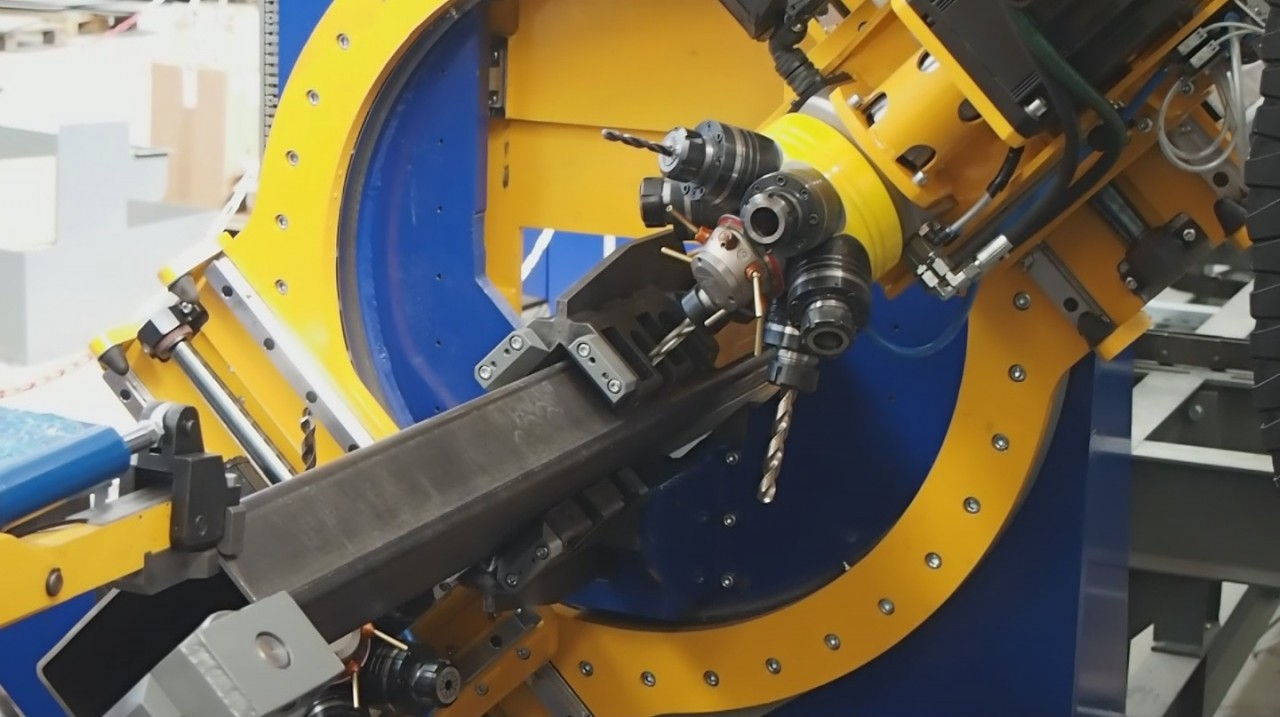

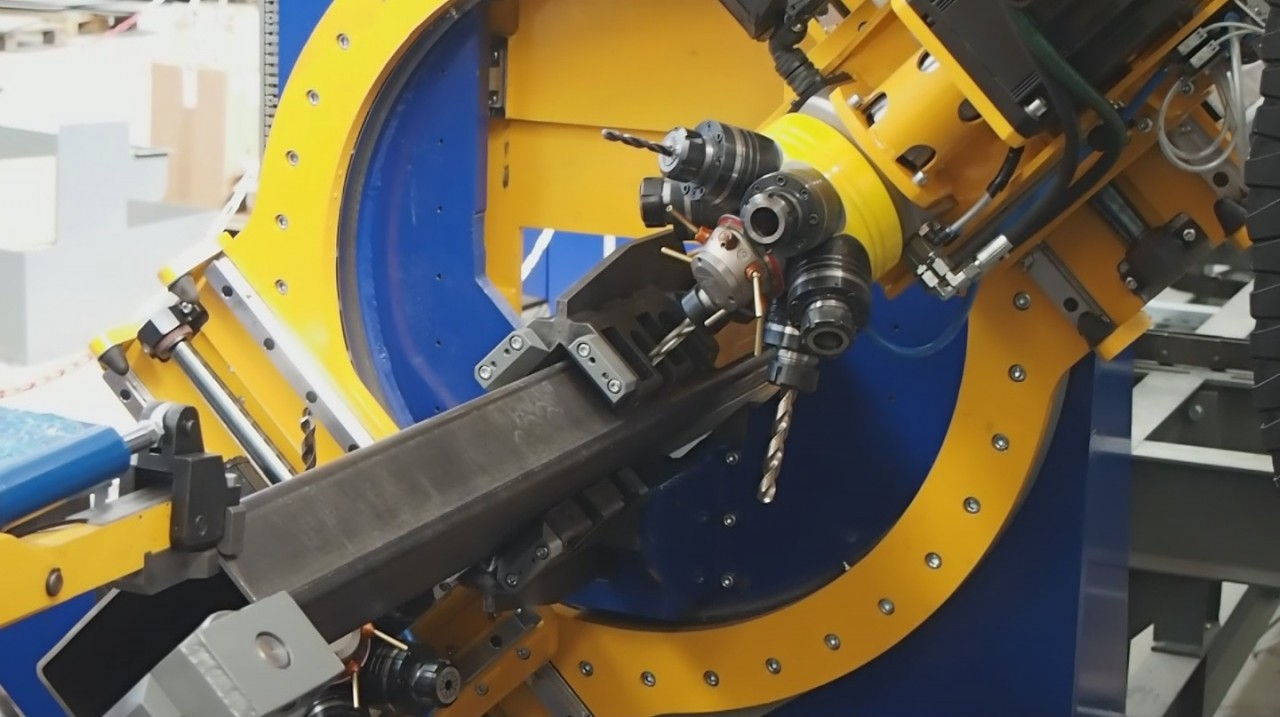

For cutting of open sections, such as I, H, U or L profiles, MicroStep has recently launched a new product – ProfileCut. Its specialized 3D rotator with a tilt of ± 120° enables cutting of structural sections without the need for their rotation in the cutting process. In addition to cutting of open profiles, ProfileCut machines can be equipped with more cutting zones, e. g. for processing of hollow profiles (cutting in the same way as on a PipeCut machine) or for sheet cutting like on a standard flat-bed machine. The functionality of ProfileCut can be enhanced by adding a drilling head for drilling up to Ø 40 mm hole diameter, with automatic tool exchange and internal cooling of drill bits, or by various marking devices.

When cutting structural steel sections, the material is loaded manually into the cutting zone; the cut profile is motionless during the cutting process and the cutting head moves around it both in the longitudinal and transverse directions. For requirements of automation of the cutting process with automatic loading and unloading of the material, a modified version of machines is supplied in which the material is loaded into the working area using a special positioning system.