The 28th annual International Engineering Fair in the Slovak city Nitra presented the latest developments in metal processing, including welding, cutting, automation and mechanization. During the four fair days from 23. – 26. May, visitors had the opportunity to see not only exhibiting companies but also innovative inventions from technical universities and colleges at the concurrent TECHFORUM exhibition.The highlight of pavilion M3 was the Technical University of Košice (TUKE) that showcased a prototype of sport sequential gearbox for vehicles, robotic arm for decontamination robots, three wheeled vehicle based on a fuel cell and metal hydride alloys, non-standard collaborative system in stochastic manipulation processes and biomedical implants.

During a series of lectures and seminars held during the first three days of the engineering fair, a wide range of topics was presented, including topics such as hot-dip galvanization, the use of collaborative robots in welding, CNC milling of furniture, the electric formula project, and 3D printing. MicroStep's Head of Marketing – Michal Kováč – also took the stage. "In the thematic block 'Innovations in welding,' we presented trends in the field of automated weld preparation on cutting machines, with an emphasis on the automation of not only technological processes but also the logistics of material flow in the factory. I believe that the numerous examples from industrial practice in countries ranging from the EU to China and Australia captivated the audience," said Mr. Kováč.

Michal Kováč with the head of Welding professionals guild doc. Ing. Jozef Jasenák, PhD.

Michal Kováč with the head of Welding professionals guild doc. Ing. Jozef Jasenák, PhD.The fair confirmed the ongoing trend of popularizing

cutting with fiber laser, that made the majority of exhibits in the CNC cutting field. "MicroStep offers a wide

portfolio of machines in this area, which, in addition to straight cutting, allow for multi-head laser cutting,

bevel cutting, tapping and countersinking, as well as industrial marking. In addition to sheet metal, we also cut

pipes and closed profiles, including full

automation," confirmed Kováč.

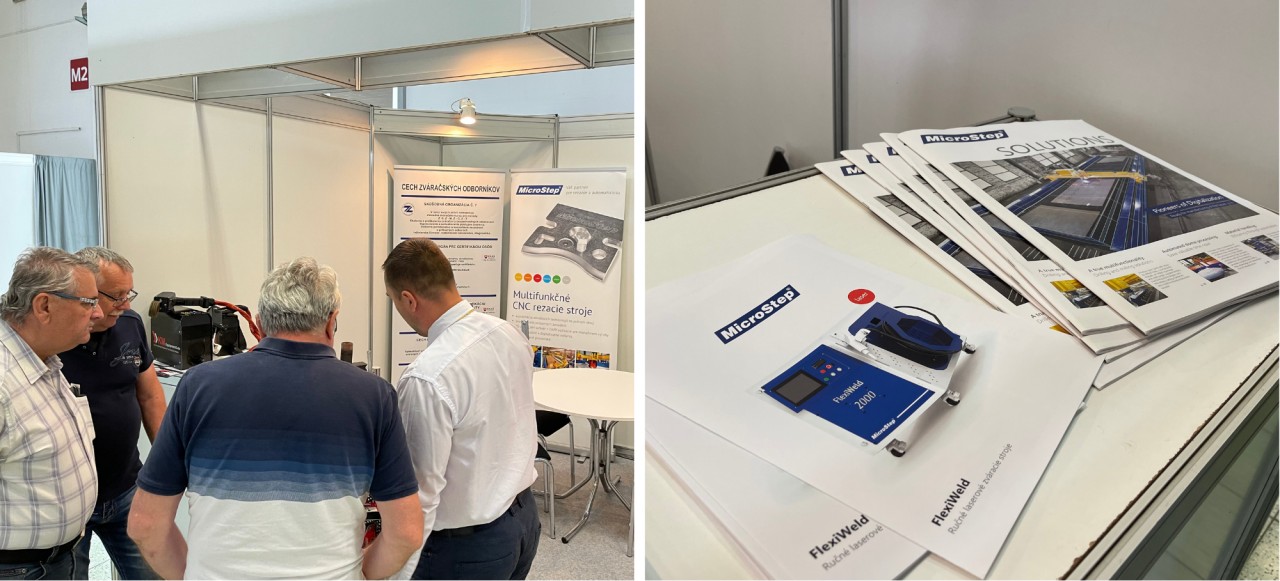

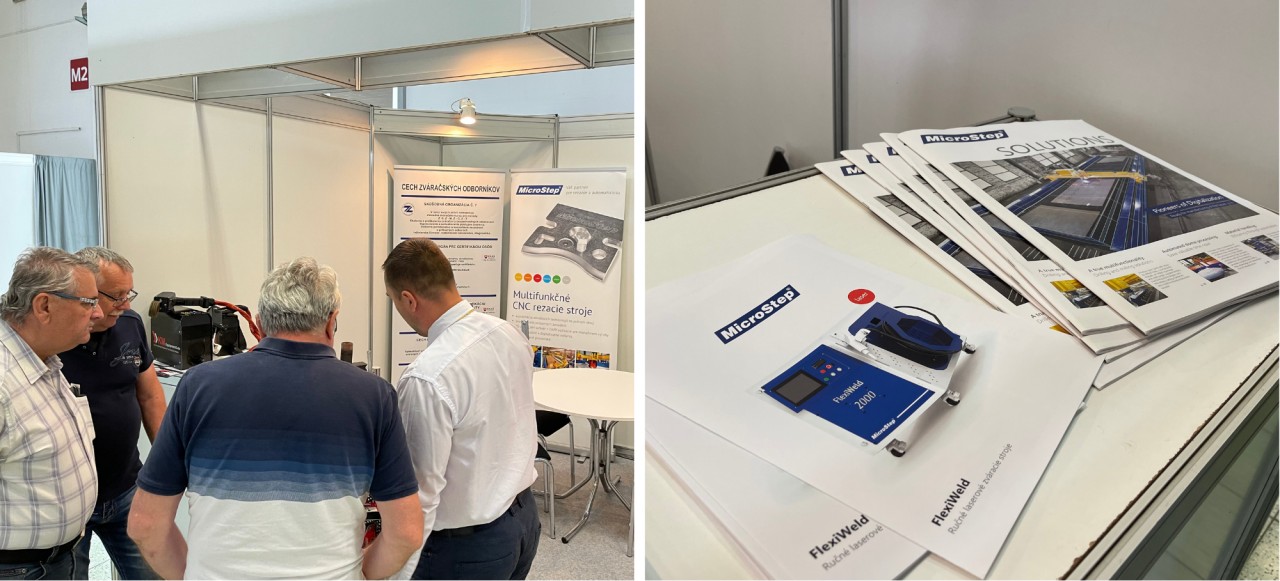

During the engineering fair days representatives of MicroStep were alo present at the booth of Welding professionals guild, with whom the company has a long term collaboration in the field of welding processes and certification, such as the implementation of the EN 1090 standard. MicroStep, with its latest product

FlexiWeld, is venturing into the field of manual laser welding, which is a fast-establishing trend in the welding of thin materials due to the stability of the process and relative ease of use.

MSV Nitra 2023 brought a lot of ideas and fruitful discussions with partners and potential customers. The fair is over, we are already looking forward to next year´s edition!

Fresh off the production line: FlexiWeld – a manual laser welding machine from MicroStep caught attention of the industry

Fresh off the production line: FlexiWeld – a manual laser welding machine from MicroStep caught attention of the industry