When Agility Subsea Fabrication wanted to replace the existing cutting machine, it was crucial to choose an effective and reliable solution. That is why they decided for MicroStep and the local supplier EIVA-SAFEX AS.“As one of the leading suppliers in the global subsea segment, we always need to deliver! Because of that, we always choose quality machines for our production. We contacted three suppliers and checked their references. Kleven Verft AS was one reference and they gave us very good feedback. We chose EIVA-SAFEX AS solution after overall assessment of technology, reliability and service”, says Thomas Nilsen-Aas, production manager at Agility Subsea Fabrication.

Dependability is important

Dependability is important“Delivery time is the key to success in Subsea Fabrication. That is why we need an efficient cutting centre, because we cannot wait for parts, because if we do, we lose the next job. Operational stability from Microstep combined with the services of EIVA-SAFEX AS gave us dependability”, Nilsen-Aas adds.

“Most problems usually get solved by remote support via the internet, but we offer quick support on site as well”, says Arild Wangsmo from EIVA-SAFEX AS

The solution

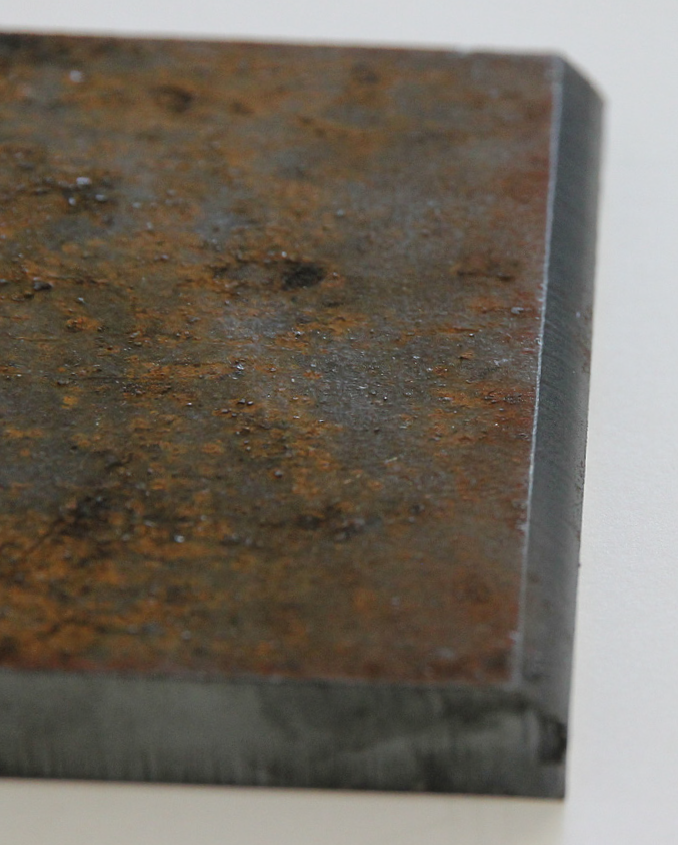

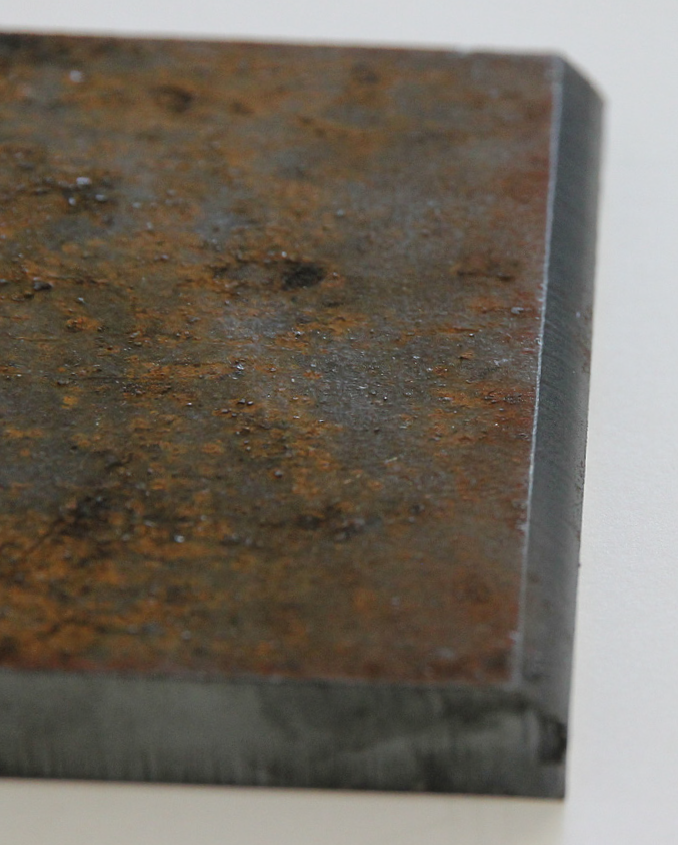

The solutionThe machine at Agility Subsea Fabrication is quite big. It can handle four sheets, 3x12m large. The gantry is installed on Messer rails and includes rotator torch with Hypertherm HPR400XD, gas station, InkJet marker and a small drill.

“Our experience after one year in use?“

“An efficient, flexible and reliable solution, that’s why we are very pleased about our choice”. That is the conclusion of production manager Thomas Nilsen-Aas.

For more infomation visi:

www.agilitygroup.no or

www.eiva-safex.noTranslated from

NorwegianOriginally published in April 2017 in Norwiegan magazine Maskinregisteret.

Official website:

http://www.tungt.no/maskinregisteret/